Sepiolite ultrafine vertical grinding mill

Sepiolite ultrafine vertical grinding mill is a highly efficient industrial powder mill. It can grind 100+ kinds of non-metallic ores into a fine powder(150-3000 mesh). High capacity, good powder quality, fineness can be adjusted freely.

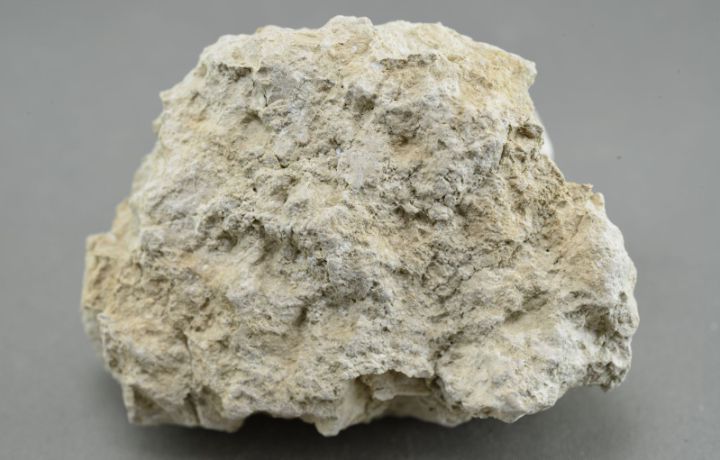

What is sepiolite?

Sepiolite is a layered silicate mineral of orthorhombic (orrhombic) crystal system. It is usually white, light gray, light yellow, and other colored clay-like masses, sometimes in the shape of a crust or nodule. The hardness of sepiolite is 2~2.5, and the specific gravity is 2.2. It can strongly absorb water and become soft when it meets water, and harden when it dries again. Sepiolite can be formed by sedimentation or altered by serpentinite.

Sepiolite crushing and grinding process:

The equipment required for the sepiolite crushing and grinding production line is jaw crusher, hammer crusher, bucket elevator, storage bin, vibrating feeder, ultrafine vertical mill, powder classifier, powder collector, pulse dust removal system, high-pressure fan, electrical control system, etc.

The large pieces of sepiolite are initially crushed by the jaw crusher, and then further crushed by the hammer crusher until it meets the feed size of the ultra-fine vertical mill.

Through the bucket elevator and vibrating feeder, the sepiolite is sent uniformly and quantitatively to the grinding chamber of the ultra-fine vertical mill for grinding.

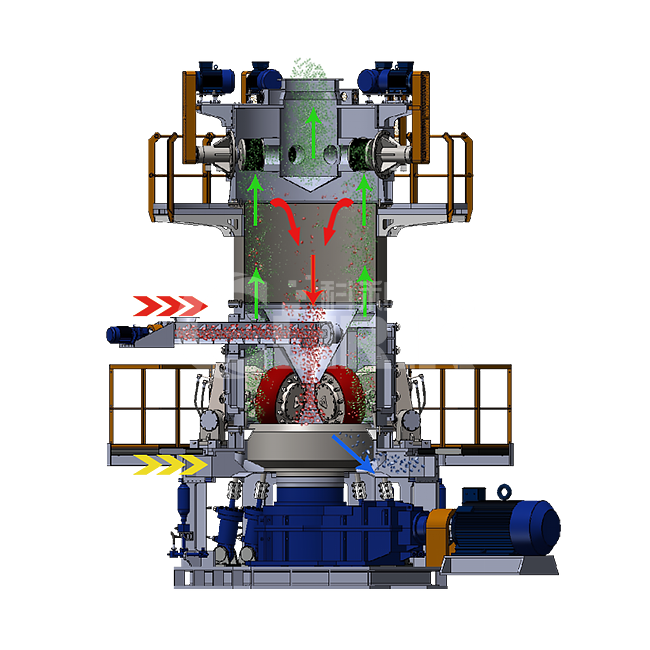

The sepiolite falls to the center of the CLUM ultra-fine vertical grinding disc through the screw feeder. Driven by the host motor, the reducer drives the grinding disc to rotate, forming centrifugal force, forcing the material to move to the edge of the grinding disc.

When passing through the grinding zone between the drum and the grinding disc, the bulk material is directly crushed under the pressure of the drum. The fine-grained materials form a layer, and the materials crush each other.

The crushed material after pulverization continues to move to the edge of the grinding disc until it is carried away by the airflow and enters the powder separator. Under the action of the powder separator blade, the coarse particles that do not meet the fineness standard fall into the grinding disc for re-grinding, and the powder that meets the standard enters the powder collector as a finished product.

For the iron blocks and other sundries in the material, when they move to the edge of the grinding disc, they will fall into the lower cavity of the mill due to their heavy weight, and then be sent into the discharge port by the scraper installed at the bottom of the mill and finally discharged out of the mill. .

Sepiolite ultrafine vertical grinding mill

The CLUM ultra-fine vertical mill is independently developed by CLIRIK on the basis of many years of experience in mill production. It integrates ultra-fine grinding, grading, powder selection and conveying.

Product features: higher capacity, better powder quality, better overall performance

Input size: 0-15mm

Capacity: 5-18TPH

Materials: limestone, calcite, dolomite, calcium carbonate, gypsum, barite, marble, talc, coal powder, etc.

Advantage of CLUM ultrafine vertical grinding mill

• Higher yield, better quality

CLIRIK specially designed the unique roller shell and liner grinding curve, which can avoid the problems of long material residence time, repeated grinding and high iron content in the grinding process of traditional mills. This design makes it easier to produce material layers, and one-time grinding can achieve high yields. It can greatly improve the working efficiency of the mill and improve the whiteness and cleanliness of the finished product.

• More energy-efficient multi-head powder selection technology

CLIRIK uses PLC control system and multi-head powder selection technology in this vertical mill, which completely solves the two major problems of "high-precision and accurate powder cutting diameter, and fast switching between different production requirements". The user can precisely control the working parameters of the equipment such as grinding pressure and speed. Compared with ordinary mills, the energy consumption of this mill can be reduced by 30%-50%.

• Double limit technology, more stable operation

In the CLUM ultra-fine vertical mill, the contact point between the roller shell and the grinding disc liner adopts electronic limit technology and mechanical limit protection technology, which can avoid the destructive impact caused by machine vibration (such as grinding roller directly hitting the grinding disc) (such as grinding roller). Direct impact on the grinding disc) to ensure the stability of operation.

• Reversible structure makes maintenance easier

In the design process of the CLUM ultra-fine vertical mill, CLIRIK fully considered the possible maintenance problems of heavy rollers, and finally developed a reversible structure. Through this structure and hydraulic adjustment system, the operator can conveniently and quickly move the grinding roller out of the machine body, inspect and replace the roller shell and liner, and perform other maintenance operations to reduce downtime losses.

Click here to get more about ultrafine vertical roller mill

FAQ:

1. Why choose CLIRIK ultrafine vertical grinding mill?

CE, ISO9001

Factory sell directly

30 years experience, professional

Sales market all over the world

2. What payments can we accept?

Accepted delivery terms: FOB, CFR, CIF, EXW, CPT, DDU, express;

Acceptable payment currency: USD;

Acceptable payment methods: T/T, L/C, Western Union;