Sepiolite Ultrafine Grinding Machine

Material introduction

Sepiolite is a fibrous hydrous silicate, generally in the form of massive, earthy or fibrous aggregates. The color is usually white, light gray, light yellow, etc., opaque and dull. Sepiolite can be divided into two types: α-sepiolite and β-sepiolite according to the shape: the former is produced as a large bundle of fibrous crystals, usually called fibrous sepiolite; the latter is often produced in the form of soil, Composed of very thin and short fibers or fibrous aggregates, it is non-toxic, tasteless, and non-radioactive. The unique structure of sepiolite determines that it has good adsorption performance, rheological performance and catalytic performance, and can be used in medicine, ceramics, casting, chemical industry, plastics, construction and other fields.

The sepiolite mill can process sepiolite to 80~2500 mesh, and there are more than 130 types of applications, such as oil, petroleum refining, adsorbent, decolorizing agent, filter agent; brewing, chemical industry, molecular sieve, used in chemical industry , sugar, wine making; medicine, ion exchangers, purifiers, brighteners; ceramics, casting, silicate, high-quality raw materials for special high-temperature resistant coatings of high-magnesium refractory materials...

Sepiolite grinding process

The sepiolite grinding process is generally divided into two types: sepiolite fine powder processing (20 mesh-400 mesh), and sepiolite ultra-fine powder deep processing (400 mesh-3250 mesh).

Process one

Large pieces of sepiolite ore are transported to the raw material warehouse by special vehicles, and then the materials are sent to the jaw crusher by forklift or manually for crushing, and the crushing is smaller than the maximum feed size of the mill.

Process two

The sepiolite ore crushed by the crusher is lifted to the storage hopper by the elevator, and the material is discharged from the storage hopper, and then fed to the main machine evenly by the feeder.

Process three

During the grinding process of the mill, the qualified products are screened by the screening system and enter the collector through the pipeline. After collection, they are discharged through the discharge valve as finished products, and the unqualified products fall into the main machine for re-grinding.

Process four

The sepiolite fine powder ground by the grinding roller of the pulverizer flows into the blower through the residual air pipe above the dust collector through the purified air flow. The qualified fineness passes through the grading rotor leaves on the top of the powder mill and enters the pulse (cloth bag) dust collector through the air duct, and is packaged in the next step.

Sepiolite Ultrafine Grinding Machine

The ultra-fine pulverizer is mainly suitable for ultra-fine powder processing of non-flammable and brittle materials with medium and low hardness, Mohs hardness ≤ 6, such as calcite, chalk, limestone, carbon black, kaolin, bentonite, talc , mica, magnesite, illite, pyrophyllite, vermiculite, sepiolite, attapulgite, rectorite, diatomite, barite, gypsum, alunite, graphite, fluorite, phosphate rock, potassium There are more than 100 kinds of materials such as ore and pumice, and the particle size of the finished fine powder can be adjusted arbitrarily between 325-3000 mesh, and the output can reach 0.4-45 tons per hour.

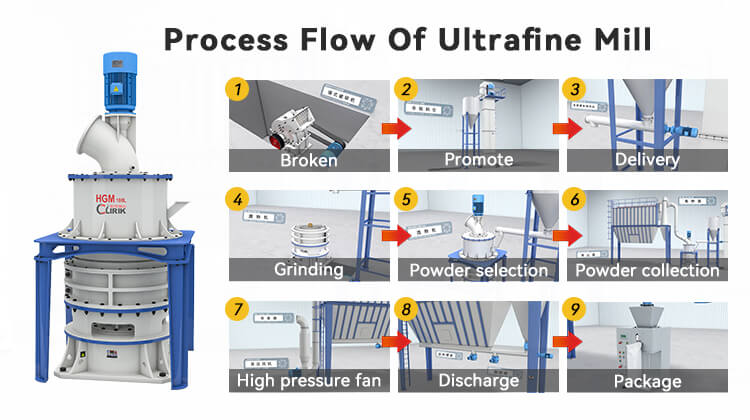

The mill production line usually includes hammer crusher, bucket elevator, storage bin, vibrating feeder, micro powder mill host, frequency conversion classifier, double cyclone powder collector, pulse dust removal system, high pressure fan, air compressor , electrical control system and other components. Large pieces of material are crushed by the hammer crusher into a feed particle size (about 1cm) suitable for the ultrafine mill, and then the fineness suitable for production requirements is achieved by adjusting the speed of the mill analyzer, and then packed into bags manually , It is also possible to configure automatic micro-powder balers and choose different types of mills according to needs.

Working principle of sepiolite ultrafine mill

When it is working, the motor of the main machine drives the main shaft and the turntable to rotate through the reducer, and the roller pins on the edge of the turntable drive dozens of grinding rollers to roll in the grinding ring raceway.

Large pieces of material are broken into small particles by the hammer crusher, and then sent to the storage bin by the elevator, and then sent to the upper bulk disk of the turntable evenly through the vibrating feeder and inclined feeding pipe.

Under the action of centrifugal force, the material is dispersed to the periphery of the circle, and falls into the raceway of the grinding ring, is impacted, rolled and ground by the ring roller, and becomes powder after being processed by the three-layer ring, and the high-pressure fan sucks the external air Inhale into the machine, and bring the crushed material into the powder classifier.

The rotating impeller in the powder classifier makes the coarse material fall back for regrinding, and the fine powder that meets the requirements enters the cyclone powder collector with the airflow and is discharged from the discharge valve at the lower part to become the finished product, while the airflow with a small amount of fine dust passes through After the pulse dust collector, it is discharged through the fan and muffler.

Performance advantages of ultrafine pulverizer:

● Energy efficient

In the case of the same finished product fineness and motor power, the output is more than double that of jet mill, stirring mill and ball mill.

● Long service life of wearing parts

Grinding rollers and grinding rings are forged from special materials, which greatly improves the degree of utilization. Generally, it can reach more than one year. When processing calcium carbonate and calcite, the service life can reach 2-5 years.

● Environmental protection, clean

The pulse dust collector is used to capture dust, and the muffler is used to reduce noise, which has the characteristics of environmental protection and cleanliness.