Mica powder ultrafine vertical mill hot sale 2021

Mica powder ultrafine vertical mill is a large-output ultrafine vertical ore grinding machine independently developed by CLIRIK. It is widely used in chemical, metallurgy, non-metallic mining and other industries in grinding non-flammable and non-explosive materials under 7 (the Moh's hardness), suitable for huge capacity producing.

What Is Mica Powder?

Mica mines mainly include biotite, phlogopite, muscovite, lepidolite, and iron lepidolite. The most used industrially are muscovite and phlogopite. Lepidolite is an important mineral raw material for refining lithium.

Mica powder is a non-metallic mineral, which contains a variety of ingredients, mainly including SiO2, the content is generally about 49%, and the content of Al2O3 is about 30%. Mica powder has good elasticity and toughness. Insulation, high temperature resistance, acid and alkali resistance, corrosion resistance, strong adhesion and other characteristics, is an excellent additive.

What Is Mica Powder Used For?

It is widely used in electrical appliances, welding rods, rubber, plastics, papermaking, paints, coatings, pigments, ceramics, cosmetics, new building materials and other industries, with a wide range of uses.

1. Paint field

Coating mica powder is a new type of functional green and environmentally friendly filler. Its unique two-dimensional flake barrier, ultraviolet light shielding, chemical structure stability and other functions can effectively improve the coating film’s anti-permeability, weather resistance, abrasion resistance and resistance. Corrosive, in addition, does not contain any radioactive elements, leading the green and environmental protection trend in the coating field. It is widely used in architectural exterior wall coatings, anticorrosive coatings, powder coatings, high temperature resistant coatings, insulating coatings, waterproof coatings, road marking coatings, radiation protection coatings and some special coatings, such as marine coatings, spacecraft thermal control coatings and food utensil coatings Wait.

2. Cosmetics

Makeup-grade mica has a unique flake structure, silky luster and smooth texture, making the powder of cosmetics as light and delicate as silk. The natural texture makes the skin have excellent affinity and crystal clear and beautiful effect, and gives cosmetics the characteristics of soft touch, soft luster, good affinity, and strong skin adhesion. It is the first choice for high-end powdery raw materials in the cosmetics industry.

In addition, the crystal transparency of mica powder can maintain a consistent intensity of makeup color, and it is also suitable for various shades of color. The unique nature of sericite can also add silky soft luster to cosmetic manufacturing. The products are widely used in many fields such as pressed powder, powder, eye shadow, liquid foundation, blush, powder and so on.

3. Plastics field

Plastic mica powder has the characteristics of high diameter-to-thickness ratio, high temperature resistance, acid and alkali resistance, and abrasion resistance. It is a natural functional powder filling material. Compared with glass fiber, mica has the characteristics of smooth surface and no warpage. Products are widely used in the fields of PP, PA, PBT, PET and other plastic modification, functional masterbatch, and plastic engineering applications.

Mica powder, with its unique and excellent properties, is filled into plastics, which can reduce the shrinkage, warpage and bending of the products; improve the mechanical properties, heat resistance, insulation and chemical stability of the products; increase the surface gloss of the products; While preventing the aging of plastics, it also expands the application fields of plastics and increases the added value of mica ore powder.

4. Electronic field

Mica powder is a new type of special functional filler, which is suitable for the technical requirements of the copper clad laminate industry. It can be used as an alternative to electronic grade silicon powder, giving the board ideal insulation, rigidity, low expansion rate, drilling processability, heat resistance and process stability, etc. performance. The material is completely chemically inert, and will not crack and deteriorate or induce reactions even at high temperatures and complex systems. In particular, it has the characteristics of greatly improving drilling efficiency, drilling quality and reducing drill bit wear. It is gradually becoming a popular material in the copper clad laminate industry.

5. Rubber field

Mica powder is an excellent rubber filling and reinforcing material. The unique structure of high-diameter-thickness ratio improves the reinforcing effect excellently. The excellent flaky crystal shape greatly improves the air tightness. The polarization effect of its own mineral crystal and the interference of water molecules between layers Effect, effectively shielding the performance of ultraviolet, microwave, and infrared rays, greatly improving the aging resistance of products.

6. Refractory material field

In the field of refractory materials, mica powder has the advantages of stable main mineral content, moderate refractoriness, stable physical and chemical properties of insulation and heat insulation; good clay adhesion, non-expansion, fast drying speed, good plasticity, and strong iron flow resistance.

7. Welding Rod Field

In the field of welding materials, mica powder is a new type of electrode coating material. Its unique combination of chemical elements can improve arc stability, reduce spatter, improve the process performance of the electrode, and solve the frequent occurrence of electrode coating cracking in the production process of electrode problem.

8. Ceramic industry

Mica ceramic is a special engineering material, suitable for the production of heat-resistant materials, insulating materials, high-temperature mechanical parts, etc., and is widely used in the electrical and electronic industries.

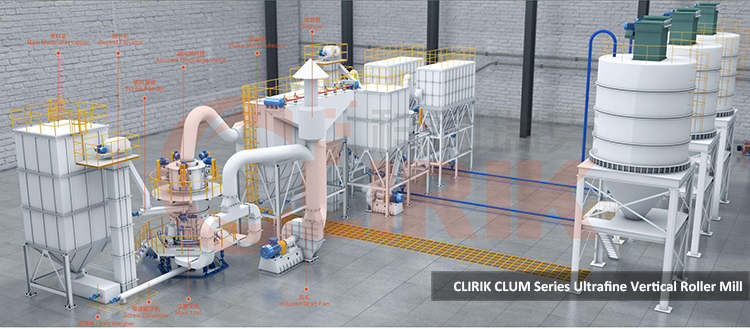

How To Make Mica Powder? - CLUM Ultrafine Vertical Mill

The main mica powder meshes are: 325 mesh, 400 mesh, 800 mesh, 1250 mesh, 2000 mesh and 3000 mesh, as well as superfine mica powder. According to the processing technology, mica powder can be divided into dry process and wet process.

Mica powder ultrafine vertical mill is a new type of ultra-fine grinding equipment integrating powder grinding, grading, conveying, secondary powder selection, and finished product packaging.

When the ultrafine vertical mill is working, the grinding wheel is driven by a motor through a reducer. The material is fed into the main machine of the vertical mill through the feed screw and falls into the center of the grinding disc. Under the action of centrifugal force, the material spreads from the center of the grinding disc to the surroundings and is rolled into fine powder. The powdery material continues to move to the edge of the grinding disc until it is taken away by the strong airflow from the air inlet and enters the high-efficiency classifier. The qualified dust is collected by the integrator, and the unqualified dust is sent back for regrind.

There are 3 models of CLUM ultrafine vertical mill, which can meet different production needs. The following parameter table is for reference only. The actual parameters will be different due to different materials and grinding environments. If you are preparing to engage in the mica powder grinding production industry, or are interested in our ore grinding machines, please feel free to contact us. We will provide free solutions according to your materials and production needs. You are also welcome to visit our company on site.

| Main configuration and production | |||

|

Model Item |

CLUM1425 | CLUM1632 | CLUM1736 |

| Working Diameters(mm) | 1400 | 1600 | 1700 |

| Number of rollers(pieces) | 3 | 3 | 3 |

| Number of classifier(pieces) | 5 | 7 | 7 |

| Power of classifier(Kw) | 5X15 | 7X15 | 7X(15~18.5) |

| Main unit power (Kw) | 250 | 315 | 355 |

| Blower power(Kw) | 200 | 250 | 315 |

| Feed size (mm) | <10mm | <10mm | <10mm |

| Moisture of feeding material | <3% | <3% | <3% |

|

Less than 2μm=34% output(t/h) |

11-14 | 13-17 | 15-19 |

|

Less than 2μm=46% output(t/h) |

7-8 | 9-10 | 11-12 |

|

Less than 2μm=60% output(t/h) |

3-4 | / | / |

|

Material: based on calcite Particle size distribution: measured by micro laser diffraction particle size analyzer in British Malvern3000 instruments |

|||

Little knowledge of mica powder that is often paid attention to:

Is Mica Powder Safe For Skin?

Mica is a natural mineral product with extremely high chemical stability. It is a completely inert substance, so it is safe, non-toxic and harmless, and suitable for the requirements of cosmetics.

1. Sun protection

Mica is one of the components of granite, and its chemical stability is like granite. Mica wafers can shield ultraviolet and infrared rays, so it is an excellent anti-ultraviolet agent for cosmetics. Moreover, it is pure natural, non-toxic and harmless, and has the advantages that synthetic organic anti-ultraviolet agents do not possess. Because the wafer is extremely thin and the covering ability is extremely strong, only a small amount of these products is needed to form a layer of anti-ultraviolet protective agent and brightening agent invisible to the naked eye.

2. Moisturizing

In addition, because the mica chip is fine, the coverage on the skin is not continuous, so it does not affect the breathability of the skin and the skin feels comfortable. Moisture cannot penetrate the mica wafers, and when used in moisturizing products, it can inhibit the evaporation of skin moisture. Therefore, the protective layer can delay the evaporation of water and improve the moisturization of the skin. It can be evenly mixed with water and glycerin, and has a fine and elastic texture. It is the first-class raw material for high-end cosmetics and the first choice for cosmetic foundations. It can be used as emulsion, cream, pearlescent Wait until ingredients.

Is Mica Powder Edible?

Mica is a general term for layered aluminosilicates such as potassium, aluminum, magnesium, iron, and lithium. Polymorphism is common, among which monoclinic crystal system is the most common, followed by trigonal crystal system, and other varieties are not common. I heard that mica powder is edible. Is this true?

Not all mica powder can be eaten directly. Although mica powder looks like flour, it cannot be directly made into food. Mica powder is most commonly used in paint, cosmetics and building materials industries. Certain mica powder can be used as a medicinal material.

Different mica has different functions. For example, industrial mica has the characteristics of insulation and high temperature resistance. Muscovite is the most used mica;

The second is phlogopite, which is widely used in the building materials industry, fire fighting industry, fire extinguishing agent, plastic and other chemical industries;

Chinese medicine mica is actually a silicate mineral muscovite, which has the effects of anti-fatigue, strengthening, antacid, antidiarrheal, diuretic, and dehumidifying. It is a health-preserving medicinal material, but it needs to be taken under the guidance of a professional Chinese physician. (Because of the thallium element contained in mica, excessive consumption can cause poisoning, leading to hair loss, gastrointestinal reactions, nervous system damage, etc.)

Edible mica powder as a traditional Chinese medicine, generally taken orally: decoction, 3-5 yuan; or into pills or powder, it has the effects of calming the nerves and relieving convulsions, stopping bleeding and reducing sores, and is considered to be diuretic and disinfection in the book "Pharmacology of Chinese Medicines" Medicine, can cure leaching disease and women take it. It also cures chronic enteritis, diarrhea in children, scarlet fever and so on. It can also be used externally to treat erosions such as burns, cuts, and eczema.