How to choose the stone powder processing equipment that suits you

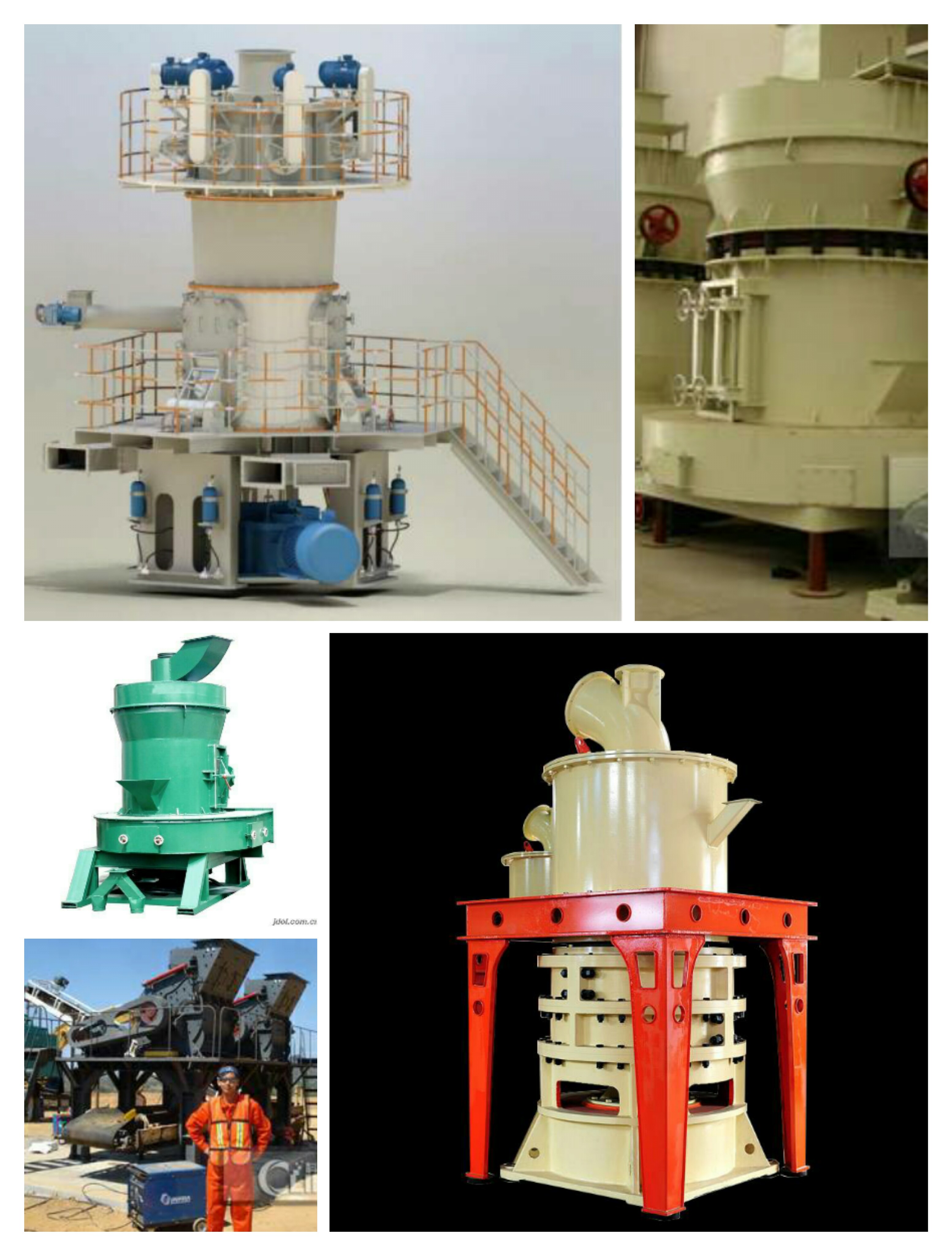

The stone powder processing equipment, also known as the grinding mill, the mining mill, etc., is a machine for grinding ore. How do customers make choices in the face of a variety of grinding equipment with varying quality in the market? Next, Shanghai Clirik introduces to you the following things to consider when purchasing stone powder processing equipment:

1. Material.

The mill can process ore-based materials. However, for some pure metals, materials that are flammable and explosive, have too much water content, and have too much hardness cannot be processed. For example, construction waste, some construction waste contains a lot of steel, the crusher can not be processed, need to be pre-treatment, in order to enter the mill. For example, some ore containing a large amount of mud, if directly fed, will block the mill.

1. Material.

The mill can process ore-based materials. However, for some pure metals, materials that are flammable and explosive, have too much water content, and have too much hardness cannot be processed. For example, construction waste, some construction waste contains a lot of steel, the crusher can not be processed, need to be pre-treatment, in order to enter the mill. For example, some ore containing a large amount of mud, if directly fed, will block the mill.

2. Fineness.

There are many different types of mills, and the processing configuration is different for different fineness. For example, the coarse powder grinding machine should be used to process the coarse powder, the fineness can reach 15 mesh; the fine powder should use the Raymond mill or high pressure grinding mill. micro powder grinding mill, the fineness can reach 425 mesh; the ultrafine vertical roller mill is used to process ultrafine powder, the fineness can reach 2500 mesh.

3. Production.

Different mills have different fineness, and the yield is naturally different. The amount of output affects the economic benefit of the user. The better the productivity, the higher the yield. For example, under the same fineness physical requirements, the high-pressure mill is more traditional than the mill. The high productivity of the powder machine, the choice of high pressure grinding is a better choice for users.

There are many different types of mills, and the processing configuration is different for different fineness. For example, the coarse powder grinding machine should be used to process the coarse powder, the fineness can reach 15 mesh; the fine powder should use the Raymond mill or high pressure grinding mill. micro powder grinding mill, the fineness can reach 425 mesh; the ultrafine vertical roller mill is used to process ultrafine powder, the fineness can reach 2500 mesh.

3. Production.

Different mills have different fineness, and the yield is naturally different. The amount of output affects the economic benefit of the user. The better the productivity, the higher the yield. For example, under the same fineness physical requirements, the high-pressure mill is more traditional than the mill. The high productivity of the powder machine, the choice of high pressure grinding is a better choice for users.