Diatomite Ultrafine Grinding Mill

Introduction of diatomite grinding mill

The diatomite mill is a kind of high-efficiency and low-consumption ultra-fine powder processing equipment designed by Shanghai Keliric R&D technology department after many times of innovation, testing and design. It has successfully replaced the complex procedures of traditional jet mill and ball mill for grinding and sorting powder, greatly reducing production cost and improving product fineness. Thousands of domestic users have proved that the equipment has the advantages of superior performance, stable quality, simple operation and convenient maintenance, and is an ideal equipment for ultra-fine powder processing.

Diatomite is a siliceous rock, a biological siliceous sedimentary rock.

1. Diatomite can be used as an additive for biological pesticides, cement and decorative coatings after being processed by an ultra-fine pulverizer.

2. Diatomite The finished diatomite used for biological pesticides also has the advantages of non-toxicity to soil, good suspension performance, moisturizing and loosening of soil.

3. Diatomite is used as an additive for cement and interior decoration coatings, which has the advantages of good ductility, high tear strength and strong compressive ability.

Scope of application of diatomite grinding mill

Mainly suitable for superfine powder processing of non-flammable and explosive brittle materials with medium and low hardness, Mohs hardness ≤6, such as calcite, chalk, limestone, dolomite, carbon black, kaolin, bentonite, talc, mica , magnesite, illite, pyrophyllite, vermiculite, sepiolite, attapulgite, rectorite, diatomite, barite, gypsum, alumite, graphite, fluorite, phosphate rock, potassium ore, More than 100 kinds of materials such as pumice, the particle size of fine powder products can be adjusted arbitrarily between 325-3000 mesh, and the output can reach 0.7-7.5 tons per hour. There are five types of HGM series ultra-fine powder mills of Shanghai Keliric Machinery Co., Ltd., namely HGM80, HGM90, HGM100, HGM100A, HGM125 (new).

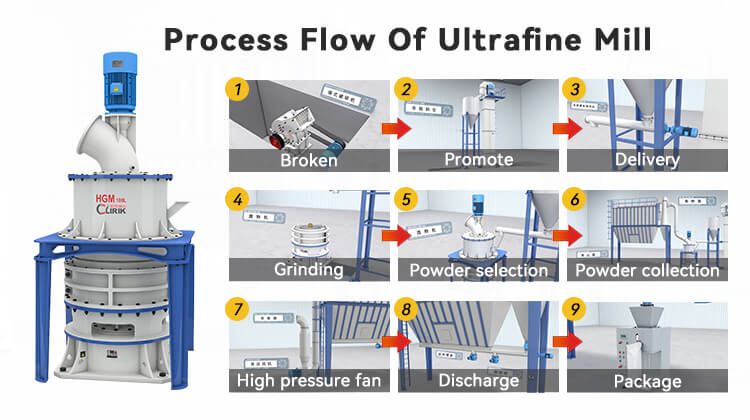

Diatomite grinding mill production line composition

The complete set of configuration includes crusher, bucket elevator, storage bin, vibrating feeder, micro-powder mill host, frequency conversion classifier, double cyclone powder collector, pulse dust removal system, high pressure fan, air compressor, electrical control system.

Working principle of diatomite grinding mill

After being crushed into small particles by the crusher, the bulk material is sent to the storage bin by the elevator, and then passed through the vibrating feeder and the inclined material guide pipe, and the material is evenly sent to the bulk material tray on the upper part of the inner turntable of the main machine.

When the mill is working, the main engine motor drives the main shaft and the turntable to rotate through the reducer, and the turntable drives dozens of grinding rollers to rotate and roll in the grinding ring raceway through the roller pins on the edge. The materials are scattered to the periphery under the action of centrifugal force, and fall into the magic cavity, where they are impacted, rolled and ground by the grinding rollers in the ring of the grinding ring. Repeated grinding into powder through three or four layers of rings.

The high-pressure fan sucks the external air into the machine by suction, and brings the pulverized material into the classifier. The high-speed rotating impeller screens it, the unqualified coarse powder falls back for regrinding, and the qualified fine powder enters the cyclone powder collector with the airflow, and the dust falls and is discharged from the discharge valve at the bottom to be the finished product.

A small part of fine dust enters the dust collector with the airflow and adheres to the surface of the filter bag. The pulse valve controls the high-pressure air flow to spray instantly from the inside of the filter bag, and the dust adhering to it will fall down due to the sudden shaking of the filter bag, and the conveyor at the bottom will send the fine powder materials collected in two places for finished product packaging. The filtered clean air is finally discharged at the outlet of the muffler.

Diatomite grinding mill performance characteristics

1. High efficiency and low consumption

Under the condition of the same finished product fineness and motor power, the output is more than 1 times higher than that of jet mill, stirring mill and ball mill, and the energy consumption is 30% lower.

2. The wearing parts have a long service life

Grinding rollers and grinding rings are forged with special materials, which greatly improves the durability. Under the condition of the same fineness of materials and finished products, the service life of wearing parts is 2-3 times longer than that of impact crusher and turbo crusher, generally more than 2 years. When processing calcium carbonate and calcite, the service life can reach 2-5 years.

3. High safety and reliability

Because there is no rolling bearing and no screw in the grinding chamber, there is no problem that the bearing and its seals are easily damaged, and there is no problem that the screw is easy to loosen and damage the machine.

4. High product fineness

The fineness of Raymond mill and other coarse grinding products is as fine as 325 mesh (47 microns). It can be adjusted arbitrarily, and the fineness can reach D97≤5μm.

5. Environmentally friendly cleaning

The pulse dust collector is used to capture dust, and the muffler is used to reduce noise, which is environmentally friendly and clean.

6. Advanced intelligent frequency conversion speed control device

By using this device, the particle size of the powder processed is more uniform, and the adjustment is convenient.