Coal gangue grinding production line equipment

Coal gangue is a kind of waste discharged from coal mine construction and production process, but it can also be reused after certain treatment. For example, the ground coal gangue can be used to make bricks, cement, light aggregates, coal gangue blocks, etc.

What are the uses of pulverized coal gangue?

● Coal gangue power generation

Coal gangue grinding adopts fluidized bed technology. When the carbon content is more than 20%, it can be used as energy and can be used for power generation.

● Recovery of coal, pyrite

The coal gangue powder after grinding can facilitate the recovery of coal, pyrite, etc.

● Used in building materials

The coal gangue grinding powder can be used in the production of coal gangue bricks, cement, light aggregates, coal gangue blocks and so on.

● Production of cement

The production of cement from coal gangue requires "two grinding and one burning": that is, the coal gangue is mixed with a certain proportion of coal gangue, ground into materials, and burned to partial melting to obtain clinker with calcium silicate as the main component. Gypsum and mixed materials, ground to a fine powder is cement. Such a production process can save the amount of coal during clinker calcination and reduce the coal consumption of the clinker. It can improve the scorchability of the raw cement meal, which is beneficial to the stability of the thermal system and improves the cement clinker.

What are the complete sets of equipment for coal gangue mill?

The process of coal gangue grinding can be divided into three parts - crushing, grinding and packaging. The specific equipment used in each part is described as follows:

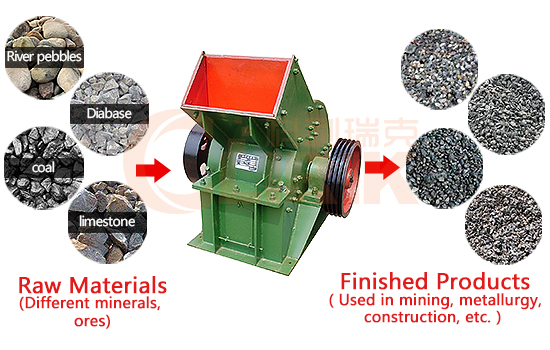

01. Coal gangue crusher

The texture of coal gangue is relatively brittle, and when it is broken, it can be broken in sections or in one section.

Segmentation crushing, that is, crushing large pieces of coal gangue in stages, first use a jaw crusher for coarse crushing, crush the large stones into small stones, and then use an impact crusher to crush the small stones into smaller particles particle.

One-stage crushing, that is, one-time forming, crushing the stones of several meters into small particles by a crusher, such as a heavy hammer crusher, which can directly crush the coal gangue to less than twenty millimeters.

02. Coal gangue grinding mill

There are many types of grinding mills on the market, but different grinding mills have different discharge particle sizes. Choosing the right powder mill can make our production more effective.

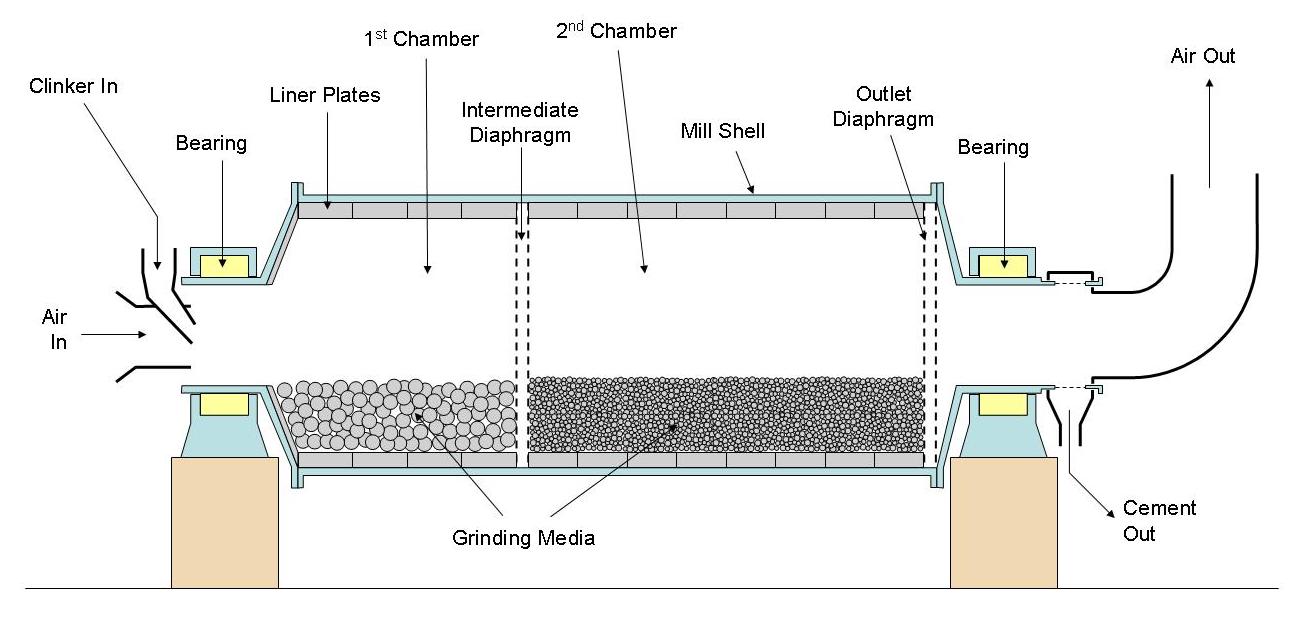

1) Ball mill

The discharge particle size of the ball mill is 20-200 mesh, and the output of a single machine can reach 615 tons.

2) Raymond mill

The discharge particle size of Raymond mill is between 80-325 mesh, and there are many kinds of ores that can be crushed, as long as the Mohs hardness is below grade 7.

3) Ultra-fine grinding mill

HGM Ultra-fine grinding mill can process very hard materials, the particle size of the finished product is between 150-3000 mesh, and it can produce other coal gangue powder with different fineness.

If you want to invest in an industrial milling production line, please feel free to consult us. CLIRIK is a 20-year-old manufacturer with standardized equipment and workshops, raw material selection, rigorous workmanship, and a complete after-sales service system, which can ensure that users can quickly start production.