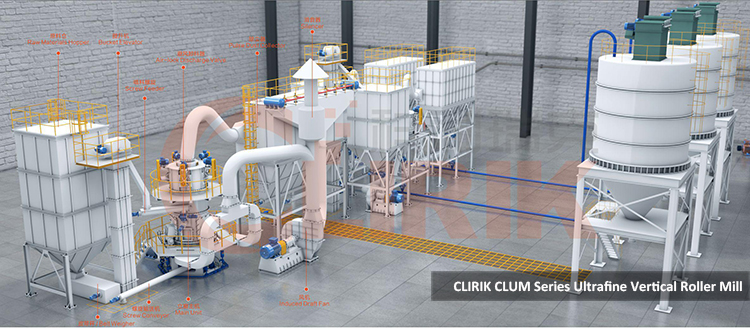

CLUM Ultra-fine Vertical Mill

Capacity: 0.2-45 t/h

Max feeding size: 30mm

Processing ability: 0.2-45 t/h

Application of CLUM ultra-fine vertical mill:

CLUM ultra-fine vertical mills are widely used in chemical, metallurgy, non-metallic mining and other industries, suitable for calcite, marble, limestone, dolomite, barite, talc, kaolin, dolomite, wollastonite, gypsum, Large-scale ultra-fine dry powder processing of non-metallic minerals such as feldspar and pyrophyllite. Especially in the field of ultrafine grinding and processing of white non-metallic minerals, it has excellent performance and can provide high-quality fillers and additives for papermaking, coatings, plastics, rubber, PVC, ink and other industries.

Main features of CLUM ultra-fine vertical mill:

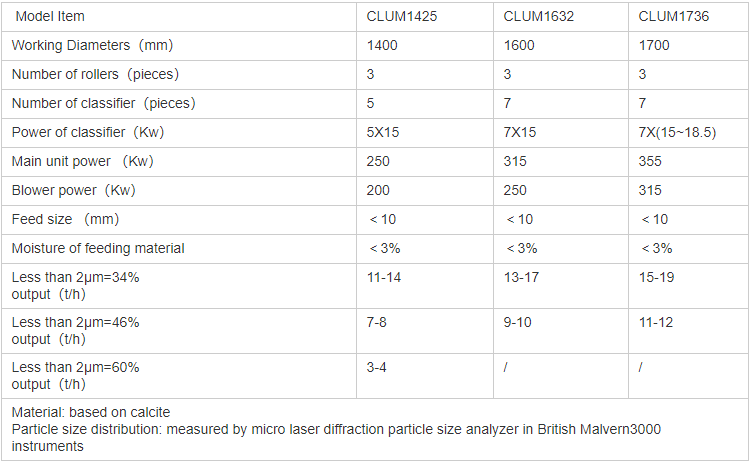

• Good quality of finished products:Finished products have high whiteness, fine particle size, narrow particle size distribution, and good particle sphericity.

The fineness D97 of the finished powder can reach 3000 mesh, and the content of 2μm can reach up to 60%.

• The finished product has low power consumption, high grinding efficiency

• Advanced control system

• Long service life

• High production capacity

• Environmental protection

The working principle of CLUM ultra-fine vertical mill:

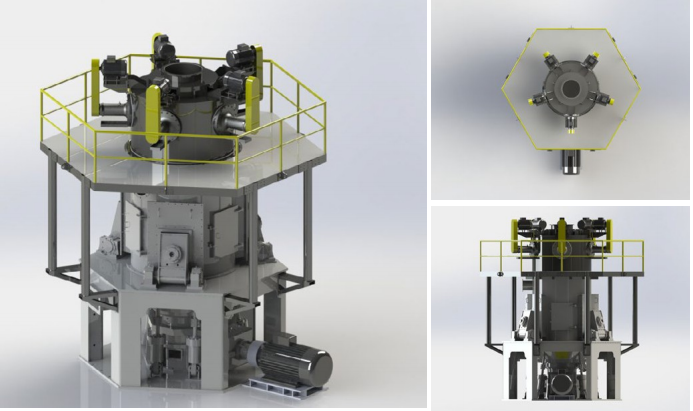

The motor of the main machine drives the milling disc to rotate through the reducer. At the same time, the airflow generated by the high-pressure fan enters the main machine from the air inlet. The material is fed into the main machine of the vertical mill through the feeding screw and falls into the center of the milling disc. Under the action of centrifugal force, the material is scattered from the center of the milling disc to the surroundings. , When passing through the roller table area on the grinding disc, the large pieces of materials are directly crushed under the pressure of the grinding rollers, and the small particles of materials are pressed and then subjected to inter-particle grinding to further pulverize until they become powder.The powdered material continues to move to the edge of the grinding disc until it is taken away by the strong airflow from the air inlet. When the material in the airflow passes through the upper separator, under the action of the centrifugal force generated by the high-speed rotating impeller, the coarse particles fall back into the grinding disc After grinding, the qualified powder passes through the powder selection system with the airflow and is collected by the dust collector, which is the finished product.

Structure and composition of CLUM ultra-fine vertical mill:

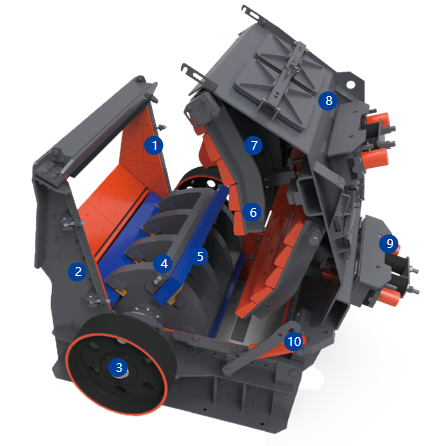

2. Lower Frame

3. Shaft Pulley

4. Rotor

5. Blow Bar

6. Impact Plate

7. Impact Rack

8. Upper Frame

9. Hydraulic Adjustment Device

10. Hydraulic Jacking Device

Specification of CLUM ultra-fine vertical mill:

our service:

Pre-sale:Free to help customers in equipment selection and scheme design

You are always welcomed to visit Clirik! Visit our prototype and showroom.

On-sale:

Strictly implement quality standards, and guarantee the quality of products shipped

Strictly implement the standard process of preparation and delivery, timely and accurate stock preparation, and rapid delivery

After-sale:

Overseas professional installation team provides technical guidance for equipment installation and commissioning

Train the start-up process, teardown method, common problems and maintenance service.

Professional after-sales service team, 24 hours response to customer needs

Customer case:

FAQ:

1. who are we?We are based in Shanghai, China, start from 2010, sell to Mid East(30.00%), Africa(20.00%), Southeast Asia(19.00%), South Asia(15.00%), North America(3.00%), South America(3.00%), Domestic Market(3.00%), Southern Europe(2.00%), Eastern Europe(00.00%), Eastern Asia(00.00%), Western Europe(00.00%), Central America(00.00%), Northern Europe(00.00%). There are total about 101-200 people in our office.

2. why should you buy from us?

• CE, ISO9001

• Factory sell directly

• 30 years experience, professional

• Sales market all over the world

• Good after sales serive

3. what services can we provide?

• Accepted Delivery Terms: FOB,CFR,CIF,EXW,CPT,DDU,Express Delivery;

• Accepted Payment Currency: USD;

• Accepted Payment Type: T/T,L/C,Western Union;

• Language Spoken: English,Chinese,French;